Application: Metering Systems Customer: Various, World Wide

There are several methods of fiscal metering in the Oil & Gas industry: they are selected dependent on the flow rate required and the media being measured.

All methods need to give you the readings in “mass flow” and therefore you will need to calculate flow, taking in mind the static pressure and temperature at that moment in time.

Mechanical Meter and Prover

With the Oil and Gas business requiring large flow pipes and being conservative in their approach to measuring, they have used tried and tested positive displacement metering with temperature and pressure sensors to provide the inputs to the measuring “computer” that will provide the fiscal metering value. The downside to this is that the package has to have a prover loop local to the metering lines, which is a primary fiscal measuring device to check calibrate the metering line and adds to the weight and size of the package.

For example, in mechanical metering run and prover, the prover has a pig in it and when you by-pass one of the metering runs through it, the medium pushes the pig round the loop. Sensors at the start and end of the loop pick up the pig passing and the time is taken. The temperature is taken and the volume of the loop is known thereby giving a flow rate to first principles.

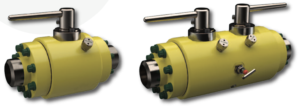

The potential to us is greater with this form of metering in Double Block and Bleed and Twinsafe products. The downside to the operator before Twinsafe is that the weight and physical size of the installation are larger and heavier.

Ultrasonic Flowmeters

With the Oil and Gas business wishing to cut down on price, size and weight, electric devices have found their way in to the metering solution. One of the metering device successes has been the admittance of non-invasive ultrasonic devices.

In simple terms, there is a sender and receiver of the ultrasonic signal attached to the outside of a honed pipe. The greater the flow rate, the greater the deflection, which is picked up by the receiver and converted into a flow rate.

Of course there are additions such as pressure and temperature that gives the mass flow figure. This device has another benefit, that there is no reduction in flow rate, as it has no restriction device in the lines.

The Oil and Gas Industry always require this form of meter on a baseplate with the computer and the isolation valves to complete a module. With Double Block and Bleed being required, the size of baseplate can be reduced with a Twinsafe on the entrance and exit of the meter. It is not unusual to see banks of these, with another one for primary measurement that is a class up in accuracy.

Coriolis Flowmeters

This is a later invention and one that has a greater accuracy than all, but is expensive and restrictive is size (Rheonik are the only ones who can do the whole range).

The Coriolis effect was initially discovered by Gustave Gaspard Coriolis in the 1830s and can be explained as the inertial force exerted on an object as a result of movement relative to a rotating frame of reference. Since its discovery it has been applied to ballistic missile trajectories, hydraulics, machine performance, ergonomics, ocean and atmospheric circulations. The use of Coriolis force as a technique for liquid and gas mass flow measurement has been firmly established for over 20 years.