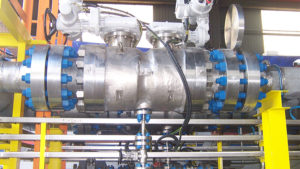

Compact Ball Valves, Compact Valves And Compact Check Valves With Swivel Flange Connections

Compact Ball Valves And Compact Twinsafe Valves

Our Compact Style Single Ball Valves are designed to provide considerable space and weight savings when compared to a traditional flanged end ball valve. Available in both floating and trunnion ball designs, the valve utilises Oliver’s proven ball valve technology and can be supplied with either manual or automated actuation.

Our Compact Style Single Ball Valves are designed to provide considerable space and weight savings when compared to a traditional flanged end ball valve. Available in both floating and trunnion ball designs, the valve utilises Oliver’s proven ball valve technology and can be supplied with either manual or automated actuation.

- Bi Directional Single Ball Valve with soft or metal seats.

- Swivel flange type construction, with butt weld hub connections.

- Floating Ball or Trunnion mounted design.

Compact Light-Weight Design

Provides space and weight saving on platforms, reduced shipping and handling costs and minimal structural support.

Threaded Valve Insert

Designed to take full working pressure. Does not rely on mating flange to hold internals.

Oliver Swivel Flanges

Designed to allow hubs to be welded into line, before split rings and flanges are fitted. Valve can be fitted with no additional ‘springing’ of pipework.

Firesafe Design

O-ring seals and metal-to-metal contact on all static joints, graphite rings provide additional resistance to leakage in the event of fire.

Other Design Features

Anti-blow out stem design shouldering on the body (rather than the bonnet), Automatic cavity relief, Low friction dry stem bearings to minimise operating torques and maximise cycle life.

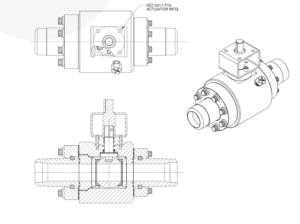

Valve can be supplied with mounting plate in accordance with ISO 5211 for actuator attachment.

Compact Ball Valve and Compact Twinsafe Ball Valve Design Features

Description – Bi-directional, trunnion ball valve.

Bore – NPS 1″ to 8″ [DN25 to DN200].

Pressure Rating – ASME Classes upto 2500.

Hydro Body Test

Pressure – 1.50 x working pressure.

Working Temperature – -50 to +400 deg F (-46 to +200 deg C).

Specifications – API6D Standard, ASME VIII DIV2, NACE MR-01-75

End Connections – Buttweld profile to ASME B16.25

Operator – ISO 5211 F10 interface for actuator.

Body and Trim Material – Alloy Steel, Stainless Steel, Duplex Steel or Nickel Alloys.

Seat Insert Material – PEEK

Stem Material – Stainless Steel, Duplex Steel or Nickel Alloys.

Stem Seal Materials – PTFE lip seal with elgiloy spring.

Fire Safe Seals Material – Graphite.

Body Seal Materials – FKM or HNBR O-rings with PTFE back-up rings.

Bolting – Alloy Steel or Stainless steel.

Flange and Hub Material – Alloy Steel, Stainless Steel, Duplex Steel or Nickel Alloys.

Split Ring Material – AISI 4130 alloy steel Xylan coated.

Oliver Features and Benefits

- Compact, light-weight design provides space and weight saving on platforms, reduced shipping and handling costs and minimal structural support.

- Threaded valve insert, designed to take full working pressure. Does not rely on mating flange to hold internals. Significant safety advantage over competition.

- Throughout design, in addition to o-ring seals and metal-to-metal contact on all static joints, graphite rings provide additional resistance to leakage in the event of fire. Competitors rely on metal to metal face contact.

- Anti-blow out stem design shouldering on the body rather than the bonnet. Significant safety advantage over competition.

- Stem seal located within valve body rather than separate valve bonnet as used by competitors. This removes a potential leak path.

- Automatic cavity relief.

- Low friction dry steam bearings to minimise operating torques and maximise cycle life. Competitors use highly stressed non-NACE stainless steel xylan coated bearings.

- In addition to the spring energised lip seal stem seal, a graphite fire safe stem seal is provided. Competitors rely on small clearances to keep stem leak to a minimum during a fire test.

- All o-rings are supplied in material which has been fully explosive decompression tested.

- Coil spring between ball and spindle provides electrical continuity to prevent static build up.

- Grease injection fitting has two inline tungsten carbide balls for maximum sealing integrity.

- Valve can be supplied with mounting plate in accordance with ISO 5211 F10 for actuator attachment, optionally a lever handle can be provided.

- All wetted materials are suitable for sour service as listed within NACE MR-01-75 / ISO 15156. Competitors used materials such as Nitronic 60 for some internals which is not listed in NACE.

Compact Single Ball Valve Specifications

| Pressure Rating | ASME Class 150 to 2500 |

| Temperature Range | -50 deg C to 200 deg C |

| Design Specification | API 6D |

| Fire Test Specification | API 607, API6FA, ISO 10497 |

| Seat Material | PEEK |

| Optional Features |

Seat and Stem Injection Points; Ball Cavity Drain and Vent Ports

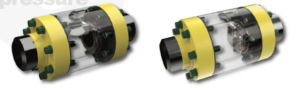

Description – Compact swing check valve.

Bore – NPS 1″ to 8″ [DN25 to DN200].

Pressure Rating – ASME Classes upto 2500.

Hydro Body Test

Pressure – 1.50 x working pressure.

Working Temperature – -50 to +400 deg F (-46 to +200 deg C).

Specifications – ASME VIII DIV2, NACE MR-01-75

End Connections – Buttweld profile to ASME B16.25

Body and Trim Material – Alloy Steel, Stainless Steel, Duplex Steel or Nickel Alloys.

Spring Material – Nickel Alloy X-750

Seat Material – Glass filled PTFE

Fire Safe Seals Material – Graphite.

Body Seal Materials – FKM or HNBR O-rings with PTFE back-up rings

Oliver Check Valve Design, Features and Benefits

- In common with ball valve, the check valve has a threaded valve insert, designed to take full working pressure.

- Profiled flapper design to allow for a fully bore flow path in the open position.

- Low stress torsion spring to maximise fatigue life.

- Metal to metal seating with PTFE seal for maximum in-service performance.

Oliver Swivel Flange Design, Features and Benefits

- Compact design compared to traditional ASME B16.5 flanges. This provides space and weight saving on platforms, reduced shipping and handling costs and minimal structural support.

- Oliver swivel flanges designed to allow hubs to be welded into line, before split rings and flanges are fitted. Valve can be fitted with no additional ‘springing’ of pipework.

- In addition to o-ring seals and metal-to-metal contact, graphite rings provide additional resistance to leakage in the event of fire.

- EPDM foam flange gasket supplied as standard with swivel flanges to minimise exposure of capscrews to environment.