Oliver Twinsafe Valves Ltd Wins Major FPSO Contract

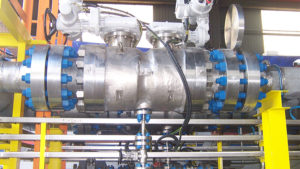

Oliver Twinsafe Valves Ltd has developed a new high temperature metal seated Double Block and Bleed ball valve for critical applications in a UK refinery. This particular development supplements Oliver Twinsafe’s metal seated range of Double Block and Bleed valves designed for operational temperatures above 340 deg C with helium leak testing.

Oliver Twinsafe Valves Ltd has developed a new high temperature metal seated Double Block and Bleed ball valve for critical applications in a UK refinery. This particular development supplements Oliver Twinsafe’s metal seated range of Double Block and Bleed valves designed for operational temperatures above 340 deg C with helium leak testing.

In conjunction with the end user, Oliver’s developed the valve using the latest sealing, bearing and coating technologies, harnessing lessons learnt from previous high temperature projects together with Oliver’s established subsea metal to metal sealing technology.

Oliver’s are confident that this is a market leading product due to its seat sealing performance and reliability at temperatures between -50 and +350 deg C. Unlike existing graphite sealing systems used by other valve manufacturers the Oliver Twinsafe design utilises a bespoke high temperature seal to maintain a reliable seat to body sealing system.

Tested in our state-of-the-art R&D facilities to the end users industry known qualification, the 2” 300 class metal seated ball valve was digitally monitored throughout a series of temperature cycles between -50 and +350 deg C. Using a patented stem seal design the valve was Fugitive Emissions tested throughout the qualifications.

Please Contact Oliver Valves Ltd on valves.dev.1int.co.uk or sales@valves.co.uk for further information. Our business is trusted globally by all the major Oil & Gas operators for our Reliability Under Pressure and our It CAN Be Done approach to client challenges.