What Is A Ball Valve And What Are The Different Types Of Ball Valves?

Let’s face it, ball valves are everywhere, they are one of the most commonly used valves in the oil and gas industry, but there’s a…

Read More

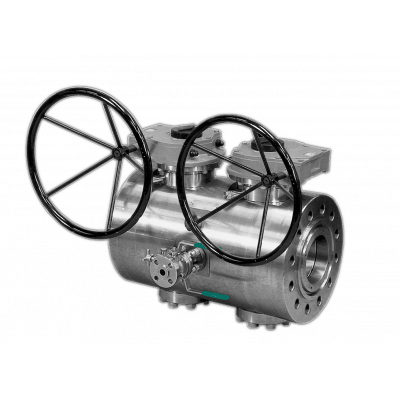

Our compact style Double Block & Bleed Valve is designed with an overall length in accordance with ASME B16:10, or shortest possible face to face dimension. The single piece body design reduces potential leak paths and ensures weight and space can be kept to an absolute minimum. Available in both full and reduced bore sizes.

Available in ASME B16.10 standard length (CSL) up to 10″ full bore and 12″ reduced bore.

Also available to Oliver standard lengths (COSL).

Trunnion mounted design from 2″ to 16″.

Studded flanged pipeline connections in accordance with ASME B16.5.

Integral vent valve with both threaded and flanged bleed connections available.

| Trunnion Ball Valves DBB Compact Design Specifications: | |

|---|---|

| Design Pressure | ASME B16.10, ASME B16.34, API 6D, ASME VIII, ASME B16.5 |

| Firesafe Standards | API 607, API6FA, ISO 10497 |

| Operating Features | Seat and Stem Injection Points; Ball Cavity Drain and Vent Ports; Double Piston Effect (DPE) Seats; PTFE Lip Seals |

| Pressure Rating | ASME Class 150 to 2500, API 6A up to 5000 API |

| Seat Materials | Soft Seats: Devlon, PEEK, PTFE & Metal Seats: Tungsten Carbide and Chrome Carbide |

| Temperature Range | -50 deg c to 200 deg C, high temperature option up to 315 deg C available |

At Oliver Valves, our industry-leading team are dedicated to engineering excellence, pushing the boundaries of valve innovation. Browse through the hot topics from within the industry, with technical information and news included.

Let’s face it, ball valves are everywhere, they are one of the most commonly used valves in the oil and gas industry, but there’s a…

Read More© Copyright 2025 Oliver Valves Ltd