Needle Valves and their uses

There are countless types of valves for use across a variety of industries and applications. One type of valve that is commonly used is a…

Read More

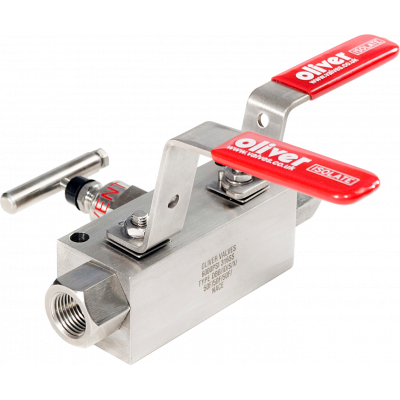

Machined from the forged bar, our “ID” Type Double Block and Bleed Valves feature two inline ball pattern primary and secondary isolating valves and a heavy-duty needle vent valve. With a range of different operating temperatures and configurations, Double Block and Bleed Valves from Oliver Valves are the superior market leader. Our Double Block and Bleed valves provide Soft or Metal seating, with 10mm, 14mm, or 20mm bore isolation valves for many applications without having to resort to traditional single isolate ball valves.

The needle valve is supplied as standard with a non-rotating tip to allow linear closure while eliminating galling. Oliver Valves’ standard “D” Type DBB range from ¼” up to 1”. DBB Valves are available in Stainless Steel, Carbon Steel, Duplex, Super Duplex and many other materials on request. All Oliver Valves products have material traceability and pressure test certificates to BS EN 10204 3.1. A unique code is stamped on all valve bodies linking them to their material and chemical analysis certificates.

Various other connection types and sizes are available for our DBB valves, from threaded to welded and hubbed. They have a Standard Temperature range up to 120 Deg C to 200 Deg C. All NPT connection threads are Single Point CNC machined.The innovative design of our Instrumentation Double Block and Bleed Valves enables them to perform in both high and low temperatures pressures and with a wide variety of media.

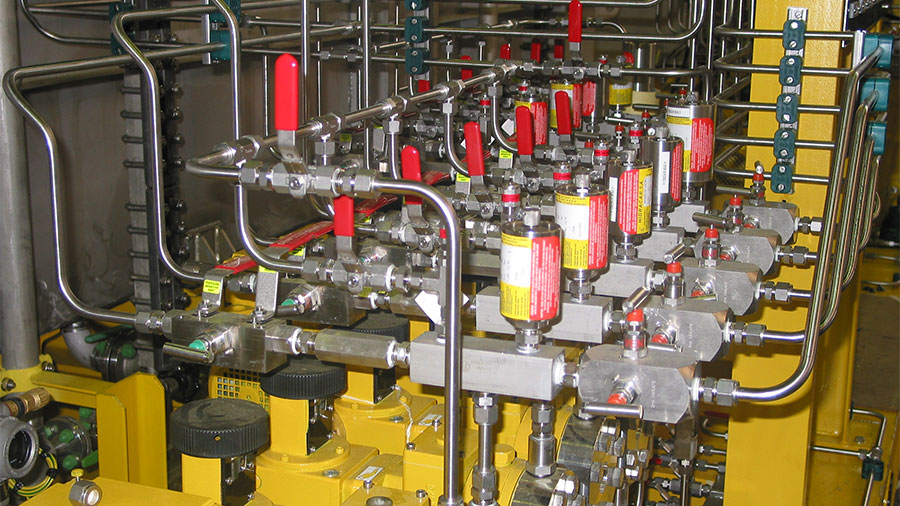

A smaller unit vs the traditional hook-up means less weight, which is significant on the top side of a platform when you combine all the pressure instrument take-offs. The typical installation is reduced from 33kg to 7kg, a weight reduction of 75%, a major benefit within the industry.

Weight reduction is also an issue when take-off is horizontal because a bending moment and could cause a critical fracture of the pipeline-interface. This is often overcome by adding more stanchions to support traditional installation, which adds even more weight.

Cost reduction is typically a 30% saving over traditional installation methods, but this could jump to 70% for valves that are created out of exotic materials. For cost-saving onsite, the testing of one component compared to different flanges, connections, etc., as well as the cost when raising purchase orders and chasing parts or goods received, can be reduced. The shipping costs are often higher and weightier when there are more parts; rises in cost can be 30% of the overall cost.

| ID Type Instrument DBB Valves Specifications: | |

|---|---|

| Bore | 10mm/14mm/20mm |

| Connection Size | From 1/4" to 1" |

| Firesafe Standards | BS6755 Pt2, API 607, API 6FA, ISO 10497 |

| Handle | Lever & 'T' Bar |

| Packing | PTFE or Graphite |

| Seats | Soft (PCTFE/PEEK) |

| Temperature | 240 Deg C |

At Oliver Valves, our industry-leading team are dedicated to engineering excellence, pushing the boundaries of valve innovation. Browse through the hot topics from within the industry, with technical information and news included.

There are countless types of valves for use across a variety of industries and applications. One type of valve that is commonly used is a…

Read More© Copyright 2025 Oliver Valves Ltd