How to Operate Valves Subsea?

Several issues need to be considered to design and configure a subsea development controlled and operated over a significant distance. Various industries use subsea valves,…

Read More

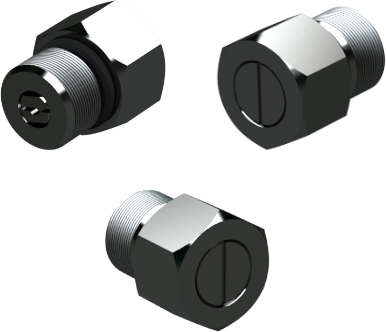

The Oliver Valvetek, Subsea Relief Valves, have a cracking pressure of 10 psi to 20 psi and a reverse sealing pressure of up to 5,000psi. Our relief valves are widely regarded as an industry standard when it comes to preventing leakage from hydraulically actuated gate valves.

Oliver Valvetek’s Subsea Relief Valves are widely used on hydraulically actuated gate valves to prevent leakage from gland seals entering actuators.

The fail close sprung poppet arrangements have been designed and flow tested to prevent pressure build-ups by relieving to the sea and closing to stop the seawater from entering.

The small-bore subsea relief valves can be supplied with a range of opening pressures and are suitable for water depths to 3050m (10,000ft). We are also able to work with customers to extend the standard 20 PSI cracking pressure where necessary.

Product Features

Key Features

Technical Specifications

| Subsea Relief Valves Specifications: | |

|---|---|

| Body Construction | BS 970 316S11 stainless steel |

| Cracking Pressure | 10 PSI to 20 PSI |

| Inlet Connection | To customers specific requirements. |

| Reverse Sealing Pressure | 5,000 PSI |

| Water Depth | 3050m (10,000ft). |

At Oliver Valves, our industry-leading team are dedicated to engineering excellence, pushing the boundaries of valve innovation. Browse through the hot topics from within the industry, with technical information and news included.

Several issues need to be considered to design and configure a subsea development controlled and operated over a significant distance. Various industries use subsea valves,…

Read More© Copyright 2025 Oliver Valves Ltd