High Pressure, High Temperature Needle Valves

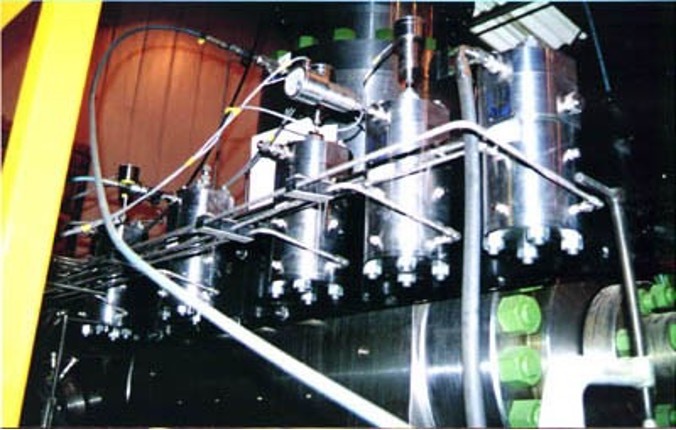

Subsea Needle Valves

At Oliver Valvetek, we provide a range of small-bore SubSea needle valves in bodies with flanged, threaded and welded end connections to suit all applications. Oliver Valvetek manufactures Diver operated, Standard Duty, Medium Duty, Heavy Duty and Hydraulically Actuated Needle Valves for subsea use.

Oliver Valvetek manufactures a range of ‘small bore’ subsea needle valves, from ¼” (6mm) bore to 1” (25mm) nominal bore. Subsea needle valves typically have an operating pressure rating up to 15,000psi and an operating Qualified temperature range of -29C to +177C and the typical water depth rating is 10,000ft or 3050m. Oliver Valvetek needle valves have a Maximum Operating Torque from 20lbf/ft to 200lbf/ft.

The different configurations of SubSea Needle Valves include:

- Hydraulically Actuated

- Manually Actuated

Operator

The needle valves can be supplied with several different operators, including Tee Bars and Cross Bars for diver operation or different shaped adaptors for connection to extension rods for ROV operation.

Operating Threads

The range of subsea needle valves includes both low torque multi-turn designs and medium torque partial turn designs.

Anti-Blowout Spindle

Each size of needle valve has a spindle designed for maximum torsional (Torque to Damage) strength and has a backseat to providing an anti-blowout safety feature.

Environmental Seals

All needle valves have seals to prevent the ingress of seawater. These have been tested to water depths equivalent to 10,000 feet (3050m).

Gland Seals

The gland seal within each needle valve has been designed with spring energised lower seal to prove dynamic adjustment of the packing gland seal in response to pressure changes.

Non-Rotating Tip

Each needle valve design has a nonrotating, self-centring, anti-galling spindle tip, which gives a positive bubble-tight shut-off.

Traceability of Materials

Oliver Valvetek subsea needle valves has material traceability; the needle valve body, tip, spindle, seal housing are manufactured as standard to API 6A PSL3. The complete needle valves are individually serialised and are provided with material and pressure test certificates to BS EN 10204 3.1.

Contact Us

If you would like more information about our valve manifolds, please contact Oliver Valves today.

Our Blogs

Latest News

Hot off the Press

At Oliver Valves, our industry-leading team are dedicated to engineering excellence, pushing the boundaries of valve innovation. Browse through the hot topics from within the industry, with technical information and news included.

How to Operate Valves Subsea?

Several issues need to be considered to design and configure a subsea development controlled and operated over a significant distance. Various industries use subsea valves,…

Read More