Needle Valves

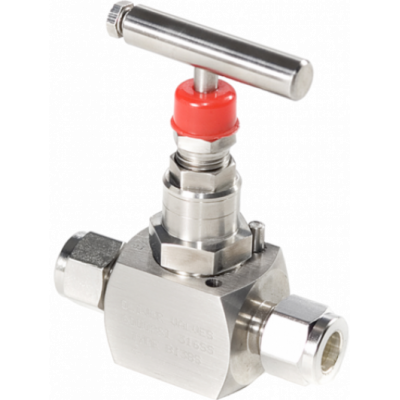

Compression ‘BI’ Type Needle Valve

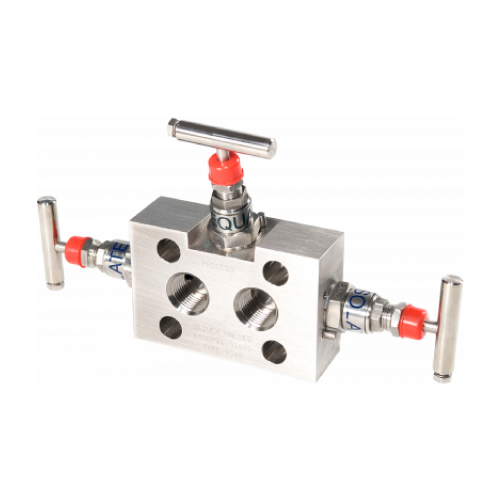

The ‘BI’ Type Single Isolating Needle Valve is designed for safe and reliable isolation. It provides a bubble-tight shutoff, non-rotating and anti-galling tip and dynamic self-adjusting spindle seal to give long service life in various applications.

Oliver Valves needle valves provide metal to metal seating and small-bore isolation valve for many applications without resorting to larger and more expensive globe valves.

Product Information

-

The ‘BI’ Type Single Isolating Needle Valve is designed for safe and reliable isolation. It provides a bubble-tight shutoff, non-rotating and anti-galling tip and dynamic self-adjusting spindle seal to give long service life in various applications.

Oliver Valves needle valves provide metal to metal seating and small-bore isolation valve for many applications without resorting to larger and more expensive globe valves.

The Compression ‘BI’ Type Needle Valve is supplied as standard with a non-rotating tip to allow linear closure while eliminating galling.

Oliver Valves’ standard needle valves are rated at 413bar (6,000psi) but can be rated at 689bar (10,000psi). Standard Temperature range from 240 Deg C up to 540 Deg C.

All NPT connection threads are Single Point CNC machined.

All Oliver products have material traceability and pressure test certificates to BS EN 10204 3.1. A unique code is stamped on all valve bodies linking them to their material and chemical analysis certificates, ensuring the traceability throughout their application usage.

Needle valve tips can be ‘interchangeable’ without special tools or spindle changes in options of hard, soft and metering tips.

Safety ‘? spindles are ‘anti-blowout’ as standard, a significant safety feature. Also, ‘an anti-removable’ steel pin is fitted into the body so that the head unit cannot be removed inadvertently.

The dust cap included with the Compression ‘BI’ Type Needle Valve protects spindle threads from ingress of dirt and is colour coded for particular services.

Refer to datasheet for full details

Our valve solutions have lead to us becoming one of the world’s leading manufacturers of instrumentation valves within the global Oil, Gas and Petrochemical industries. If you would like more information regarding our needle valves, please contact Oliver Valves today!

Product Enquiry

If you would like more information regarding our needle valves, please fill out the form below, or contact us directly on +44 (0) 1565 632 636 or sales@valves.co.uk.

Related Products

Needle Valves

Compression ‘BI’ Type Needle Valve

The ‘BI’ Type Single Isolating Needle Valve is designed for safe and reliable isolation. It provides a bubble-tight shutoff, non-rotating and anti-galling tip and dynamic self-adjusting spindle seal to give long service life in various applications.

Oliver Valves needle valves provide metal to metal seating and small-bore isolation valve for many applications without resorting to larger and more expensive globe valves.

Product Information

-

The ‘BI’ Type Single Isolating Needle Valve is designed for safe and reliable isolation. It provides a bubble-tight shutoff, non-rotating and anti-galling tip and dynamic self-adjusting spindle seal to give long service life in various applications.

Oliver Valves needle valves provide metal to metal seating and small-bore isolation valve for many applications without resorting to larger and more expensive globe valves.

The Compression ‘BI’ Type Needle Valve is supplied as standard with a non-rotating tip to allow linear closure while eliminating galling.

Oliver Valves’ standard needle valves are rated at 413bar (6,000psi) but can be rated at 689bar (10,000psi). Standard Temperature range from 240 Deg C up to 540 Deg C.

All NPT connection threads are Single Point CNC machined.

All Oliver products have material traceability and pressure test certificates to BS EN 10204 3.1. A unique code is stamped on all valve bodies linking them to their material and chemical analysis certificates, ensuring the traceability throughout their application usage.

Needle valve tips can be ‘interchangeable’ without special tools or spindle changes in options of hard, soft and metering tips.

Safety ‘? spindles are ‘anti-blowout’ as standard, a significant safety feature. Also, ‘an anti-removable’ steel pin is fitted into the body so that the head unit cannot be removed inadvertently.

The dust cap included with the Compression ‘BI’ Type Needle Valve protects spindle threads from ingress of dirt and is colour coded for particular services.

Refer to datasheet for full details

Our valve solutions have lead to us becoming one of the world’s leading manufacturers of instrumentation valves within the global Oil, Gas and Petrochemical industries. If you would like more information regarding our needle valves, please contact Oliver Valves today!

Product Enquiry

If you would like more information regarding our needle valves, please fill out the form below, or contact us directly on +44 (0) 1565 632 636 or sales@valves.co.uk.